MFS designs, develops and manufactures customized robotics plants and automated machines for specific applications in every industrial sectors.

MFS designs, develops and manufactures customized robotics plants and automated machines for specific applications in every industrial sectors.

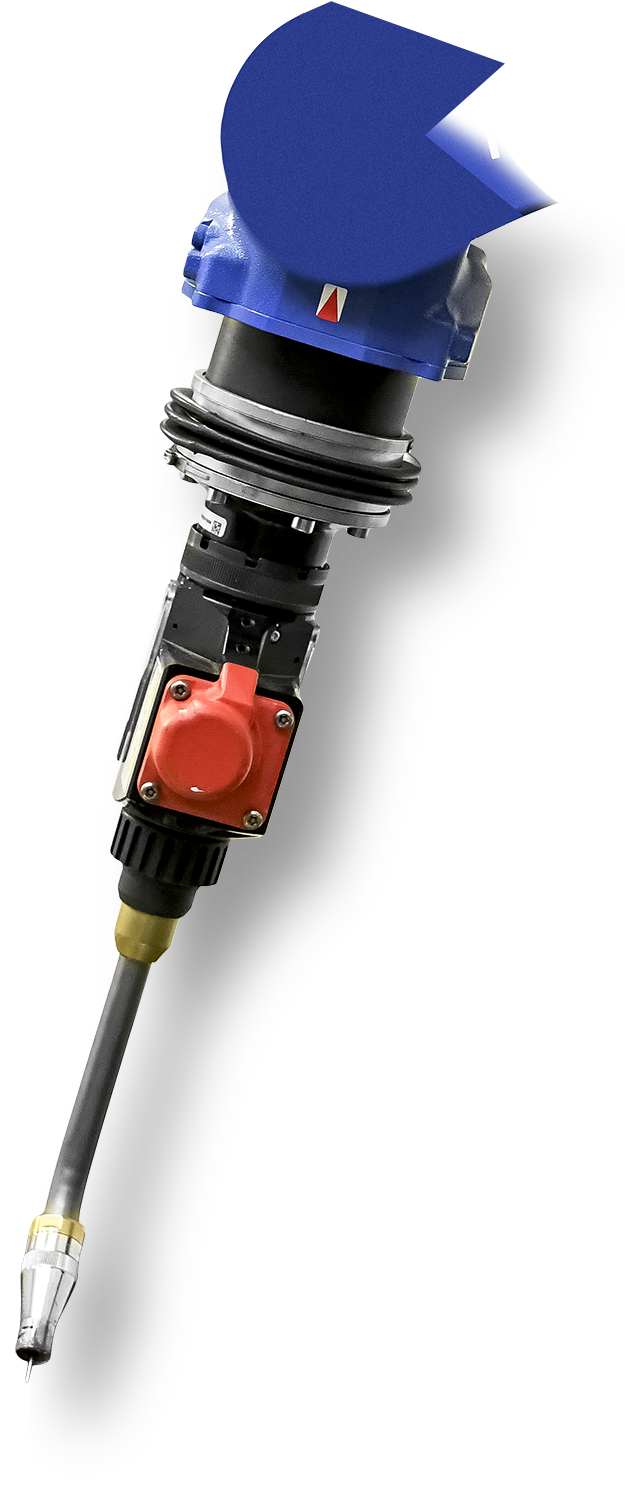

Thanks to the experience of Fani's family in welding sector, MFS had developed a high level of know-how: it designs and implements high-tech applications in the sector of welding and automation. We choose and integrate the most innovative technological solutions available on the market, according to the Customer application.

MFS design and manufacture robotized systems according to customer shopfloor layout available. Our technical department partners with the customer in the development step, in order to optimize and raise the quality standard and production efficiency. Research and Development are the substratum for being able to offer a product that follow at maximum strategic vision of our company.

It is a compact robotic welding equipment dedicated for small assemblies.

It is a smart robotic welding equipment with a double rotating station.

Robotized MFS equipment for palletizing boxes, bottles and jars.

Our robotized plants benefit from tax credits for investment in new capital goods commensurate with their acquisition cost.

MFS works in partnership with all the major robot manufacturers, including: Yaskawa, Kuka, Hyundai, Fanuc, Universal Robot.

Construction solutions conceived, designed and built according to the customer's layout.

With the design reviews done together with the customer, the adherence of the development to the expectation of the latter is ensured. Then, the constructive realization of the plant is completed in our workshop, at the end of which prototypes are made (where required) and support is given for welding qualification processes.

Customer Specifications Requirement Sharing

Development concept in synergy with the customer

Mechanical setup, fine tuning and integration

KICK-OFF MEETING

Customer Specifications Requirement Sharing

DESIGN FREEZE

Development concept in synergy with the customer

DELIVERY

Mechanical setup, fine tuning and integration

Simplifying, speeding up and optimizing costs are targets we are constantly working on. Industry 4.0 is a goal that we want to make a reality for our customers thanks to the know-how we have acquired. Our robotized plants are interconnected and remotely accessible. Its are equipped with the SAFETY PLS system for a superior level of safety and with Control Panel, simple and intuitive, for the interface between man and machine. These, and many other features, allow MFS robotized systems to fully meet the requirements to benefit from the benefits of Industry 4.0.

The future is already here and we are ready for this challenge. If you also want to be part of our project, contact us form more information about our products and how to improve your business production.