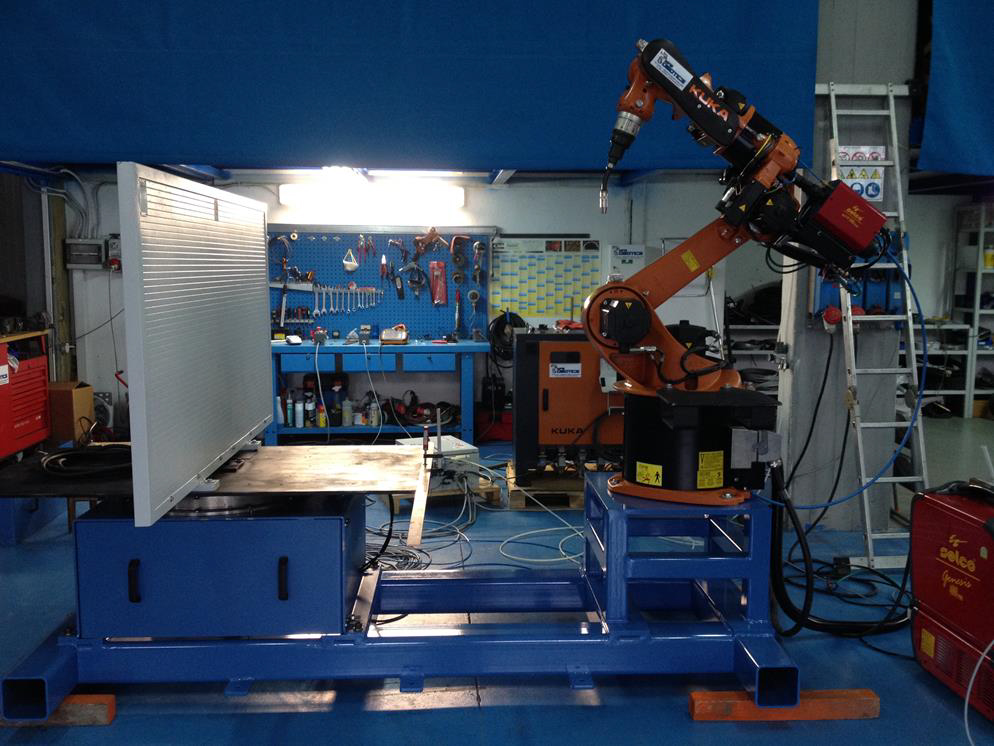

MFS is a leading company in the industrial robotic automation sector. It conceives, designs, develops and manufactures robotic plants and automated machines dedicated to specific customer applications, in all industrial sectors. Safety, quality, cost optimization and lean manufacturing are the guidelines of our organization. We transfer with passion these principles on our plants, supporting our customers in a constantly and continuously. We operate completely and autonomously as to guarantee the “turnkey” delivery of our machinery.

Our plants are all built with digital revolution approach: thanks to the Internet Of Things our machines allow our customers to access the tax policies related to Industry 4.0. MFS SERVICE has the ability to remotely access the customer’s plant, where support is required for a fault and anomaly resolution. So by help-desk support, are resolved most of the requests for the support: for the remaining part is guaranteed the maintenance service at the customer shopfloor in a short time.

MFS provides a complete integrated after-sales service and scheduled maintenance, aimed at keeping the plant operational and safe, for maximum efficiency at low cost.

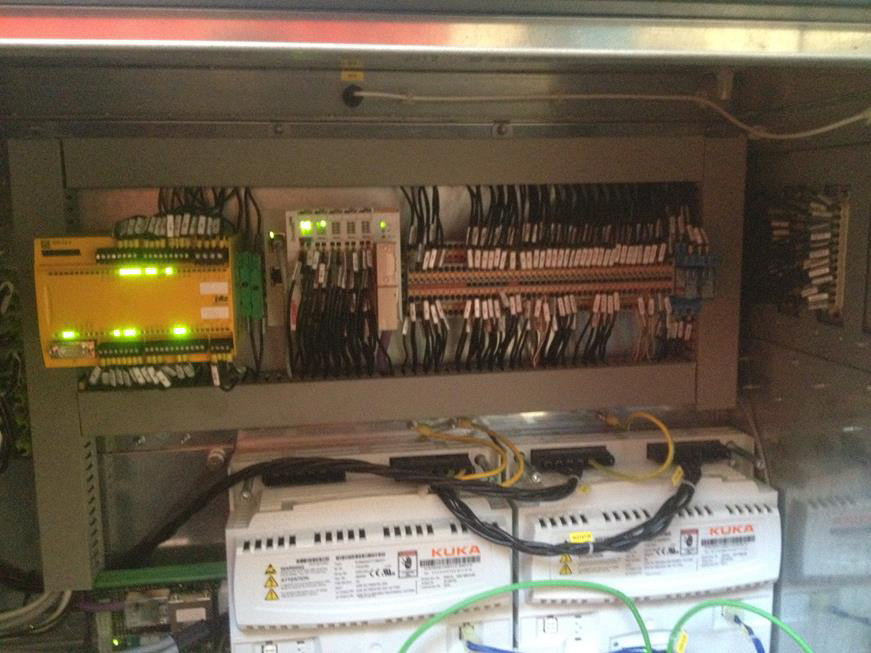

Technical and specialized maintenance in electromechanics, with robot programming, automated welding and dedicated software.

Remote diagnostics and remote assistance (with historical database of downtime of plants ) and direct contact with technicians.

We perform industrial plant cleaning, total regeneration of plant and cadenced technical cleaning.

To promote maximum efficiency, we perform routine maintenance, ordinary/extraordinary maintenance schedules and annual maintenance contracts.

Service of spare parts of obsolete material such as controls, buttons, cables, etc…

Training of maintenance technicians and production personnel.

For plants in use, obsolete and/compromised, we develop innovative solutions that, through a complete overhaul, totally renew the plant.

Revisione elettro-meccanica dell’impianto, con rigenerazione o sostituzione di parti usurate.

Aggiunta di nuove funzionalità, fino all’introduzione dell’IOT (internet delle cose) e del pacchetto Industry 4.0

Increased productivity and quality standards thorough the implementation of specific customized solutions.

Installation and restoration of components and safety systems of the plant with adaption to current regulations.

The reconversion of the plant solves the problems related to the specific production process for the application. The functional test highlights the implemented changes and the correct use of the changes done in compliance with the regulations in force.

Looking for a way to improve your production process? We are the answer to your question. Simplify, speed up and optimized costs are targets we are constantly working on.

The future is already here and we are ready for this challenge. If you too would like to be a part of our project, contact us for more information about our products and how to improve your business production.